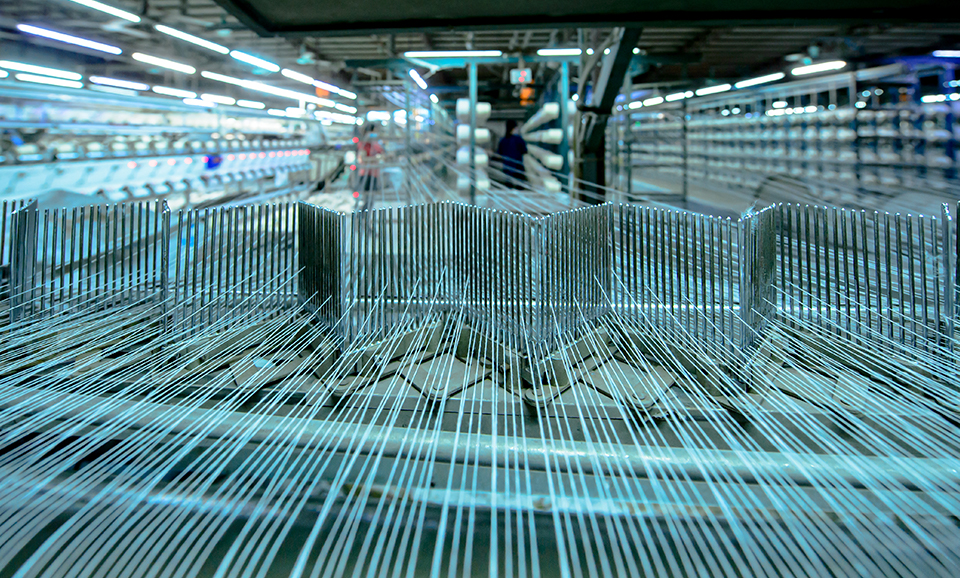

Beam warping is the 1st step for denim manufacturing. We use high level brand and high level materials to keep our products high quality. And during beam warping ,we have the chance to check the yarns 2nd time,to pick out the week cones,and to keep our products excellent stability.

read more

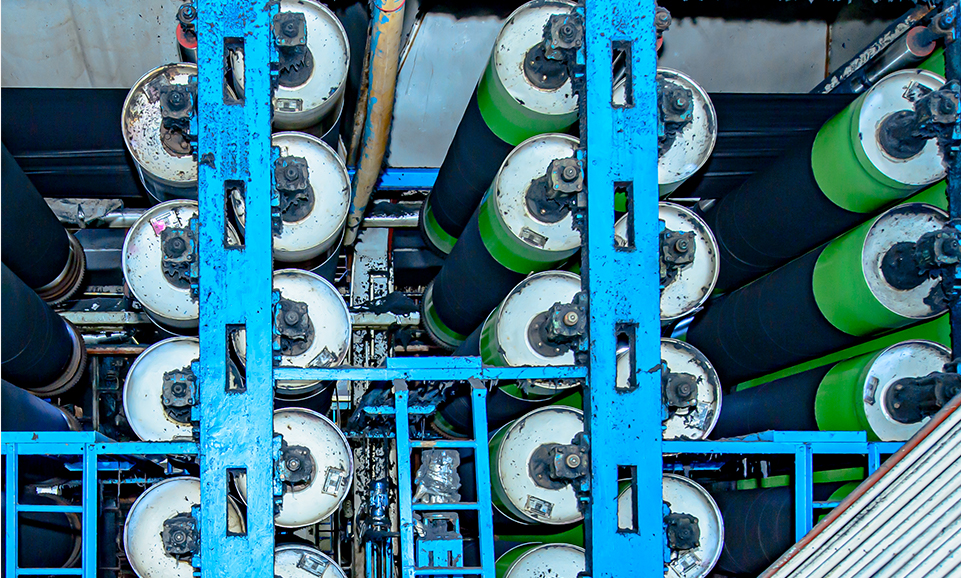

The soul for denim is dyeing. We are very good at it. We use new materials to keep the color shining. The machines are long and the dyeing vats are big enough to make the fabric color as deep as possible. Even using the best dyeing machine, the dyeing engineer and the workers are still the most important. Our engineer has more than 40 years experience on this denim dyeing industry, and our workers are careful with their work.

read moreOur weaving machines are all Picanol brand. The machines are wide and new, and just been replace for recent years. We can do power stretch denim with width more 180cm,and keep the width stable. And for last year ,we bought 35 new jacquard denim machines to provide the new series of jacquard denim .

read more

Our end processing machines are old, but our engineer has more than 30 years experience. Now the width of fabrics are becoming bigger and bigger, so we modify our machines to adapt the new designs of the market.

read moreAfter the goods arriving our warehouse, our workers will check the goods for the 2nd time to avoid mistakes, and then pack the goods with customers' demand.

read more